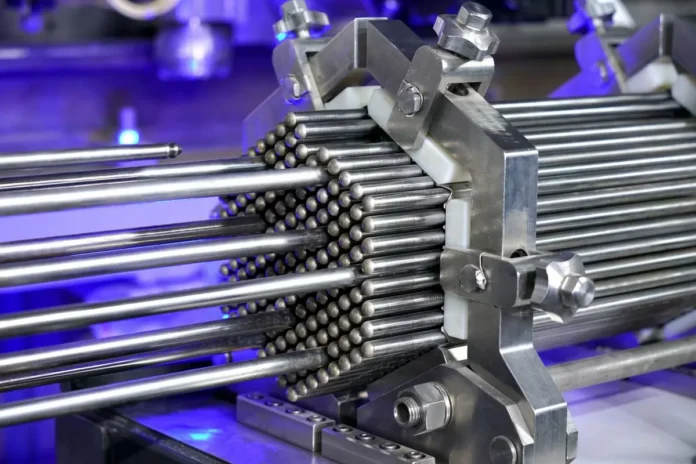

The fuel fabrication/refabrication module is the first of its kind in the unique fourth generation nuclear energy complex. This innovative technology is set to revolutionize the way we produce and utilize nuclear energy, making it safer, more efficient, and more sustainable.

Nuclear energy has long been a controversial topic, with concerns about safety, waste management, and the potential for nuclear weapons proliferation. However, with the development of fourth generation nuclear technology, these concerns are being addressed and nuclear energy is being transformed into a clean, reliable, and sustainable source of power.

The fuel fabrication/refabrication module is a crucial component of this transformation. It is responsible for the production and recycling of nuclear fuel, ensuring a continuous supply of fuel for nuclear reactors. This is a significant improvement from previous generations of nuclear technology, where fuel was only used once and then disposed of as waste.

The module works by taking in depleted nuclear fuel from reactors and using advanced processes to extract usable fuel from it. This fuel is then refabricated into new fuel rods, which can be used in reactors again. This process greatly reduces the amount of nuclear waste produced, making nuclear energy much more environmentally friendly.

But the benefits of the fuel fabrication/refabrication module go beyond waste reduction. It also improves the safety and efficiency of nuclear energy. By recycling and reusing fuel, the module reduces the need for uranium mining, which can be a hazardous and environmentally damaging process. It also decreases the risk of nuclear accidents, as the module can remove and safely store any radioactive materials that may have built up in the fuel.

Furthermore, the module is designed to be highly automated and self-sufficient, reducing the need for human intervention and minimizing the risk of human error. This makes nuclear energy even safer and more reliable.

The fuel fabrication/refabrication module is also a key component in the development of small modular reactors (SMRs). These smaller, more flexible reactors have the potential to bring nuclear energy to remote areas and developing countries, providing them with a clean and reliable source of power. The module’s ability to recycle and reuse fuel is crucial for the success of SMRs, as it allows for longer periods of operation without the need for refueling.

The development of the fuel fabrication/refabrication module is a testament to the continuous innovation and improvement in the nuclear energy industry. It is a result of years of research and development, and its implementation marks a significant milestone in the advancement of nuclear technology.

But the module is just the beginning. It is the first of many innovative technologies that will make up the fourth generation nuclear energy complex. This complex will include advanced reactors, waste management systems, and other technologies that will make nuclear energy even safer, more efficient, and more sustainable.

The fuel fabrication/refabrication module is a game-changer for the nuclear energy industry. It addresses many of the concerns surrounding nuclear energy and paves the way for a brighter and cleaner future. With its implementation, we are one step closer to achieving a world powered by clean and sustainable energy.

In conclusion, the fuel fabrication/refabrication module is a crucial component of the unique fourth generation nuclear energy complex. Its ability to recycle and reuse nuclear fuel not only reduces waste but also improves safety and efficiency. This innovative technology is a testament to the continuous progress and potential of nuclear energy. With the fuel fabrication/refabrication module, we are ushering in a new era of clean and sustainable energy production.