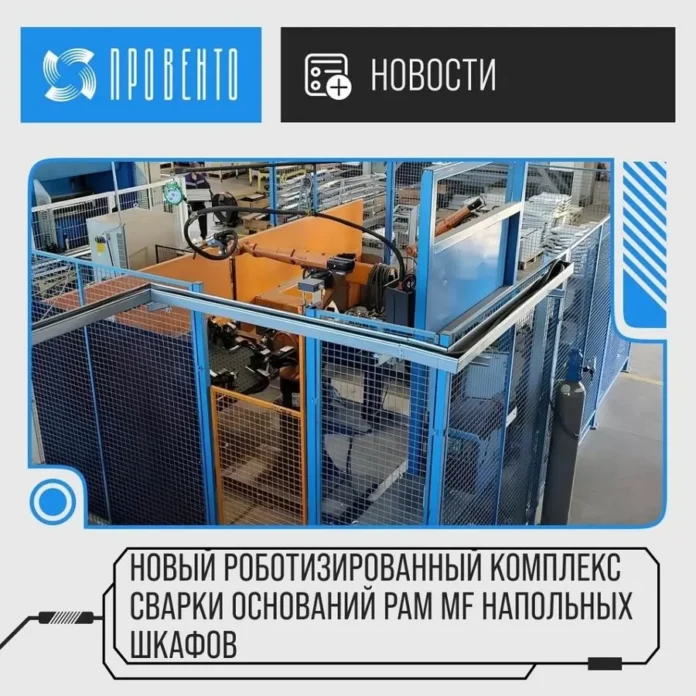

“Provento” presents an automated complex with rotary tables for welding the bases of MF floor cabinets!

When it comes to manufacturing high-quality furniture, precision and efficiency are key factors. This is especially true for the production of floor cabinets, which require precise welding of their bases to ensure stability and durability. However, manual welding processes can be time-consuming and prone to human error, leading to inconsistencies in the final product. That’s where “Provento” comes in, offering an innovative solution to streamline the welding process and improve the overall quality of MF floor cabinets.

“Provento” is a leading company in the furniture manufacturing industry, known for its cutting-edge technology and commitment to providing efficient and reliable solutions. With their latest offering, an automated complex with rotary tables for welding the bases of MF floor cabinets, they have once again raised the bar for the industry.

So, what exactly is this automated complex and how does it work? The complex consists of a series of rotary tables that are designed to hold the bases of MF floor cabinets in place during the welding process. These tables can be easily adjusted to accommodate different sizes and shapes of cabinet bases, making it a versatile solution for furniture manufacturers.

One of the key features of this complex is its fully automated process. Once the cabinet bases are placed on the rotary tables, the complex takes over, ensuring precise and consistent welding of the bases. This eliminates the need for manual labor, reducing the risk of human error and increasing productivity. The complex also has a built-in quality control system that checks the welding parameters and ensures that each base meets the required standards.

Another advantage of “Provento’s” automated complex is its speed. With the ability to weld multiple cabinet bases simultaneously, the complex significantly reduces the time needed for the welding process. This not only increases efficiency but also allows manufacturers to meet tight deadlines and fulfill large orders in a timely manner.

In addition to its efficiency and precision, the “Provento” complex also offers a safe working environment for employees. The automated process eliminates the need for workers to be in close proximity to the welding area, reducing the risk of accidents and injuries. This not only ensures the well-being of employees but also saves manufacturers from potential legal and financial consequences.

But the benefits of “Provento’s” automated complex don’t end there. The complex is also environmentally friendly, as it reduces the consumption of energy and materials. With its precise welding process, there is less material wastage, leading to cost savings for manufacturers. Additionally, the complex runs on electricity, eliminating the need for gas or other harmful emissions.

The “Provento” automated complex is not just a game-changer for furniture manufacturers, but also for the end consumer. With its precise and consistent welding, the complex ensures that MF floor cabinets are of the highest quality, providing customers with long-lasting and durable furniture for their homes or offices.

In conclusion, “Provento’s” automated complex with rotary tables for welding the bases of MF floor cabinets is a revolutionary solution for the furniture manufacturing industry. It offers speed, efficiency, precision, and safety, all while being environmentally friendly. With this complex, “Provento” has once again proven its commitment to providing cutting-edge technology to improve the production process and deliver high-quality furniture. So, if you’re a furniture manufacturer looking to enhance your production process, “Provento” is the name to trust.